Are you searching for the right Kitchener yardbird chicken plucker that easily de-feather the poultry birds without problems?

You need more time when you pluck chicken feathers with your hands. The situation is very tough when you pluck the feathers of multiple birds just by hand.

If you are working in the chicken/poultry processing farm, then you of course use the defeathering machines for defeathering of multiple chickens or other birds.

I know that plucking the feathers of poultry birds like chickens is not easy work.

Now, you are finding the solution to solve that issue. Don’t worry about the defeathering process. I think you have come to the right place to find the solution to de-feather the chicken.

I know, you may know the automatic poultry plucking machines. But you don’t use it. This is the reason why you are confusing what type of chicken plucking machine you should collect.

Why is Plucker Machine Reliable

For better efficiency, a developed poultry defeathering machine is needed. (source)

At first, I thought that rotating force can be used in chicken defeathering. So I have searched if this mechanism is available or not. The good news is that I have found that kind of mechanism which is known as a plucker.

Then, I found another problem by using traditional rotary pluckers. Some people got into an electrical accident while using this type of chicken feather removal machine.

To avoid this electrical accident, I have searched for more data and luckily found the information of a circuit breaker which is also used for some poultry/chicken feather cleaning machines.

So I quickly started to search for this kind of yardbird poultry plucker. After searching a lot, I have finally found the plucking machine with a circuit breaker.

If you don’t have time then you can try this recommended plucking machine. Otherwise, you should collect the right defeathering machine from the marketplace.

But before that, you need to know the basic general knowledge about the plucker. For this reason, here, I will share some factors about this chicken feather cleaner. These factors you must know before purchasing any de-feather plucker drum.

So don’t skip…

Best Pick: Yardbird Chicken Plucker

It includes a heavy-duty motor power (1.5 HP) which produces a smooth rotational force to the dynamic fingers for the chicken plucker machine. The working diameter of the plucker drum is 20 inches.

You can pluck all kinds of birds under 7 kilograms. It includes a GFCI facility for the protection of users. You can clean it quickly because it is well designed for proper cleaning.

For easy movement, two wheels are attached to it so that you can easily move to any place when necessary. Finger rods are available with rubber so that the finger rods can’t do any harm to the chicken’s body.

There is a cord for an electric connection. You can easily connect this machine by using the cord.

The body of the plucker drum is made of stainless steel for long-lasting use. So the durability of the stainless steel chicken plucker gives a positive impact to you.

Pros

- Easy to maintain

- Portable

- Electricity safe

- Has the system of easy cleaning

Cons

- It is not compatible with upper 7kilogram birds

Runner Up and Alternative Plucker Machine

If you can’t collect the best reliable plucker, then you don’t need to be upset. There is another stainless steel and feather removal Kitchener chicken plucker (as an alternative) available that can also solve your problem. Now, I will give the information about that feather cleaner.

It also has the durability for longer-lasting. Because the body of this plucking drum is made of metal (stainless steel). It has two wheels for moving from one place to another easily.

You can pluck the normal size of 2 chickens at a time for just 15 seconds! This machine will save your valuable time spontaneously. For safety purposes, a GFCI switch is also included in it. This GFCI will protect you from overflow current. An electric cord is available for electric connection.

The design of this feather cleaner is made for easy maintenance. The size of this feather cleaner is well designed. So you can keep it in any location. Besides, you can rapidly clean it.

Pros

- Has more durability

- Easy clean

- Portable

Cons

- It is not compatible with upper 6-7kilograms birds

For What Plucker Machine is Used for?

A Plucker machine is one kind of de-feather drum that is used for plucking poultry birds like chickens, turkey, goose, quail, and other birds. Maximum time people use this machine for defeathering chicken.

But you can use it regularly for ducks and other poultry birds. There are many types of chicken pluckers in the marketplace and they may be different according to body construction.

Some chicken defeathering machines are built with plastic drums and other de-feather drums are built with metal bodies. Nowadays the metal body of the plucker is growing popular day by day.

Recently, the stainless steel body of the poultry drum plucker stands in the top position in the marketplace.

Factors You Need to Know Before Buying Plucker Machine

1. GFCI Protection

Ground fault circuit interrupter (GFCI) is a circuit breaker that is used in electric functions for user protection. When any electric accident happens, the circuit breaker disconnects the electricity instantly.

So it is important to include GFCI in any electric plucker machine. So my suggestion is that you should check the GFCI availability in your required chicken feather plucker machine. The good news is that here the recommended plucker has GFCI for the protection of the user.

2. Durability

Metal structured plucker machines have more durable construction than plastic structured plucker machines. If you want to operate it for a long-lasting, then my suggestion is that you should collect the metal body structure of the de-feathering machine.

For rustproofing, you can select the stainless steel body structure of the plucker machine. Here the suggested automatic chicken cleaning machine has a stainless steel body for long-lasting use.

3. Size and Capacity

A 20-30 inches diameter plucker machine needs a maximum of 15 seconds to pluck a normal size chicken. That means you can pluck around 220-240 medium size chickens by using a 20 inches (around) diameter of a plucker machine.

You can place that size of plucker machine in a small area where you want to place it. So the capacity of any plucker is also a matter for a start-up poultry businessman. So the capacity of this de-feather drum depends on the bird size.

4. Speed

The speed of any plucking process depends on the stiffness or smoothness of rubber rods (natural plucker rubber fingers). If there is no rubber in any fingers, then automatically there will be a low rotation speed of the poultry plucking machine.

Normally rubber finger included normal size (20-30 diameters) of plucker machine has around 300RPMs rotation speed. This is a required automatic chicken plucker spin according to the motor capacity. This is also a better speed for plucking the feather quickly with better performance.

So I want to tell you that you should check the availability of rubber fingers of any plucking machine before purchase. Before collecting this type of de-feather drum you should check high-powered motors for getting better performance.

5. Easy Clean

A better design of a de-feather drum has a system of easy cleaning. If you want to collect a reliable de-feathering machine, then you can clean it easily.

6. Portable

If any plucker includes a wheel for easy movement, then it will be easier to transport quickly. So you should check this facility before buying any de-feather drum.

7. Budget

If you really want to save a huge amount of time for plucking feathers, I think, budget is not a factor for you, if you have a large poultry business.

Now, I will share with you the most important thing about the basic idea of plucking machines that you really need for collecting the right machine.

So don’t skip it and continue reading the function of this machine.

Functions of Defeathering Machine (Chicken Plucker Parts)

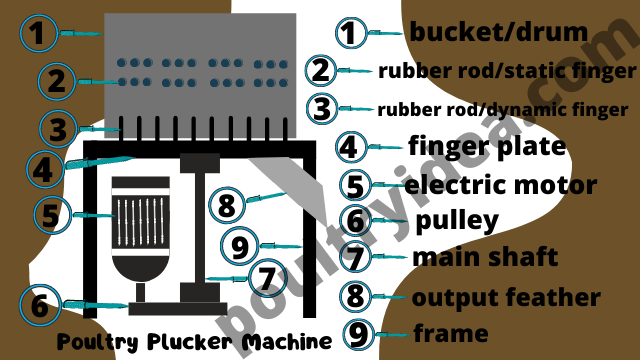

There are 9 basic parts/types of equipment in the normal plucking machine. It is made with a simple design. So you don’t need to worry about the function of it. So here I will try to introduce these parts with easy words and picture identification.

Bucket/Drum

It is the place where you keep chickens for plucking the feathers. This section is like a drum that has space for keeping the chicken’s body.

The normal diameter of the drum is maybe 20-28 inches. When you power the motor, then this drum rotates with chickens. In this picture, here is the drum that I have mentioned number one.

Rubber Rod/Static Finger

The static finger is like a hexagonal bolt. Do you see that type of bolt? Static fingers are adjusted to the drum wall. The rubber material is covered in these fingers so that there is no damage to the chicken’s body. These fingers don’t rotate.

So these fingers are called static fingers. In some areas, these fingers are known as static rubber rods. In this picture, here are the static fingers that I have mentioned in number two.

Rubber Rod/Dynamic Finger

These rubber rods are like static rubber rods or fingers. But the difference is that these rods are adjusted at the bottom side(finger plate) of the drum. These fingers rotate when you power the plucker machine. So these fingers are called dynamic fingers.

For removing the feathers from birds, these fingers play a vital role. These soft plucking fingers don’t hurt the chicken body. In this picture, here are the dynamic fingers that I have mentioned in number three.

Finger Plate

This is the plate which I have mentioned number 4 in this picture. It is a round plate. Dynamic fingers are adjusted in this finger plate.

After getting the power from the motor, this finger plate starts rotating. Then automatically dynamic fingers also start rotating.

Main Shaft

The main shaft is the long metal rod that is connected with the finger plate. This shaft receives rotating power from the pulley and gives this power to the finger plate.

In this picture, here is the main shaft which I have mentioned in number seven.

Pulley

In this picture, I have mentioned this pulley in number six. This pulley includes two metal wheels and a belt.

This pulley received the power from the motor and then transferred this power to the main shaft. Pulley may be driven by chain drive or belt drive.

Electric Motor

Now, I will tell you the most important part about electric motors. All of you are also familiar with this electric motor. In the plucker, this motor gives power to the pulley.

When you connect the cord to the electrical plug, then this motor starts giving the rotating power to the pulley. This is the reason why the pulley also starts rotating. In this picture, here is the motor which I have mentioned in number five.

Output Feather

For clearing or cleaning chicken’s feathers, there is an output tunnel which I have mentioned in number eight in this image. This output tunnel is adjusted with the finger plate.

Frame

The last part of the plucker is the frame which holds the total parts of the plucker. I think you have already understood the function of the frame of that de-feather drum. In this picture, here is the frame which I have mentioned in number nine.

How to Use Plucker Machine

After reading the function of the plucking machine, I think you can understand the basic idea of the de-feather drum. You have also known the different parts of it.

Now, I am telling you how to use the general plucking machine. So keep reading to know the use of it.

First, collect the right plucking machine. Confirm that the GFCI circuit breaker is included in it. This circuit breaker stops the electric flow during an accident. Now you should place this feather cleaner in your required position. Make sure that it has been placed nicely.

Then, you clean the collected plucker before using it. After cleaning this feather cleaner, ready the number of poultry birds that you want to pluck the feather.

Next, connect the cord of this feather cleaner to the electric power source. After the electric connection, now you can keep the chicken in the drum of feather cleaner.

If you use a 20 (around) inches diameter feather cleaner, then my suggestion is that you should keep one chicken in it.

But wait…

Before putting that chicken in the feather cleaner, you need to do scalding. Now you can ask me what scalding is.

Before removing the feathers of any chicken or poultry birds, you need to bathe that chicken in hot water (55-77 celsius) for some seconds. This method is called scalding. After scalding, the feathers of the chicken will be soft.

Now removing the feathers of that chicken will be easy. This is the fastest way to pluck poultry chickens and other wild birds.

After that, put that chicken in that feather cleaner and switch on the machine. After switching on, you will see that the chicken that you have put in it, is rotating. At the same time give some water (with a water pipe or hand) to that rotating chicken.

Finally, after 15 seconds, you will see that all the feathers of that chicken will be removed. Now switch off the machine if you don’t have more chicken. If you have more chicken, then continue the total process again.

Now I can guess that you can understand how to use a chicken plucker. At the same time, you also know how poultry plucker machines work. By using this machine, you can remove quail feathers.

For plucking the turkey, you can put 3-5 turkeys in this plucker at a time. Now I think you can understand the total basic features of the plucker.

Remember: You can’t pluck frozen birds in it. Besides, no plucking machine is suitable for plucking frozen birds. All de-feathering drums/feather cleaners are suitable for non-frozen birds for defeathering.

My Viewpoint on the Plucker Machine

In the summary section, I just want to tell you that you should have a basic idea before buying any de-feather drum. For this, I have also shared some important factors about this de-feather drum that are really important for you.

You know that a de-feather drum is a mechanical designed structure. So you need to take care, after using it.

For a clear concept, I have also shared the function of the basic plucking machine. After reading this function, you will easily know the different kinds of parts of the plucker machine.

You will also understand the working procedure of it. This will help you to maintain that feather cleaner properly. You don’t need to be a mechanical specialist to operate this cleaner. Just you need to follow the guideline spontaneously.

Here, I have also shared the information about how to use this machine. I think it will be helpful to those who don’t have any idea about it.

You may use it for all kinds of birds for defeathering feathers. But you should keep alert about the size of the birds. Because any feather cleaner has a limited capacity for plucking.

I think you have understood the capacity of this cleaner.

If you don’t have any idea about the capacity of this cleaner, then you should read the topic “capacity of plucking machine” which is in the factors section of this post.

If you are eager to start a poultry business and want to produce chicks, then you will need the egg incubator and other poultry accessories.

Finally, I want to tell you that, If you really have some time, then you can read the feather cleaner-related questions and answers in the FAQ section.

Frequently Asked Questions (FAQ) About Plucker Machine

What Else is Required When You Start Plucking Chickens?

Normally you can pluck any birds by using only a plucking machine. But it will be better if you use hand gloves and freshwater for hygiene.

You should use a knife for cutting the legs of any poultry bird. Without cutting poultry legs, you can’t pluck the feather easily. It will be better to cut the legs before plucking the feather.

What is the Best Reliable Chicken/Poultry Plucker?

If you read the factors that I have written above the post, then I think you have got the detailed answer to this question. You should check the availability of the circuit breaker, steel body material for longer-lasting, high protected cord for safe electric connection, etc.

What Time Does it Take to Pluck a Chicken by Hand?

Normally when you want to pluck a chicken without a plucking machine, then it takes around 4-10 minutes. This time may vary for well-practiced hand pluckers (manual defeathering by man) and unpractised hand pluckers (manual defeathering by man). But by using a chicken feather remover machine, everyone can pluck a chicken within 15 minutes!

Do Poultry Birds Bounce Out From Plucker Drum?

During plucking birds, normally it can’t come out from the plucker drum because of the static fingers. These static fingers control the bounce of plucking birds.

The bounce of birds is created for the rotational force of the dynamic plucker machine. This dynamic force is needed for plucking the chicken feather.

What Temperature of Hot Water is Needed for Plucking a Chicken?

Normally hot water is used for making the feather and skin soft. If you use hot water, then it will be easier for you to defeather a chicken. You should keep the temperature of hot water between 55-77 celsius.